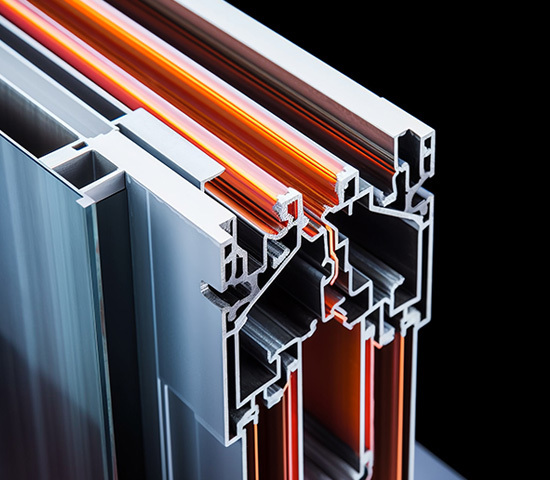

Aluminum Ingot Line

HONTENG®Hongteng Electrical Equipment Co.,Ltd is mainly engaged in the manufacture of complete sets of equipment in the metal thermal processing industry and the integration of the entire production line.

Capacity: 1250mm

Melting Time: 40-50Mins

Melting Temperature:

Recovery Rate:

Tilting Type:

Control System:

Category:

Product description

Total power needed

410KW

HONTENG®Hongteng Electrical Equipment Co.,Ltd is mainly engaged in the manufacture of

complete sets of equipment in the metal thermal processing industry and the integration of the

entire production line. Provides overall plant design for steel smelting, rolling, casting, forging, and heat treatment, as

well as solutions for the recycling of scrap metal such as steel, copper, and aluminum. The main

products are medium frequency melting furnace, medium frequency heating furnace, waste steel, copper, aluminum secondary melting furnace, molten steel refining and rolling, open and closed

cooling tower, medium and

high frequency surface quenching equipment, steel production line and other complete production

line equipment. We can provided A to Z Turnkey project for customer!

Oversea training/installation/maintenance severice supported. We can provide APP on line viewing factory production scene, remote inspection service .

keyword:

Previous:

Previous:

Product application

RELATED MACHINES

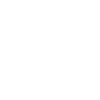

Reducer Tilting Aluminum Melting Furnace

The reducer tilting aluminum melting furnace is used to melt scrap aluminum, including cans, wires, etc. The capacity ranges from 100kg to 3 tons. Welcome to inquiry if you're interested.

Hydraulic Tilting Aluminum Melting Furnace

The hydraulic tilting aluminum melting furnace has stable rotation and sufficient turning power and is widely used to produce aluminum ingots.

Electric Aluminum Melting Furnace (Fixed)

HTGP electric induction aluminum melting furnace is suitable for smelting various scrap aluminum, such as waste cans and aluminum alloy materials. It has a fast melting speed, low burning loss rate, high recovery rate of 92%, and low power consumption.

Gas-fired/Oil-fired aluminum melting furnace

HTGP natural gas or light crude oil aluminum melting furnace can melt aluminum, copper, zinc, etc. It is specially designed for areas lacking electricity.

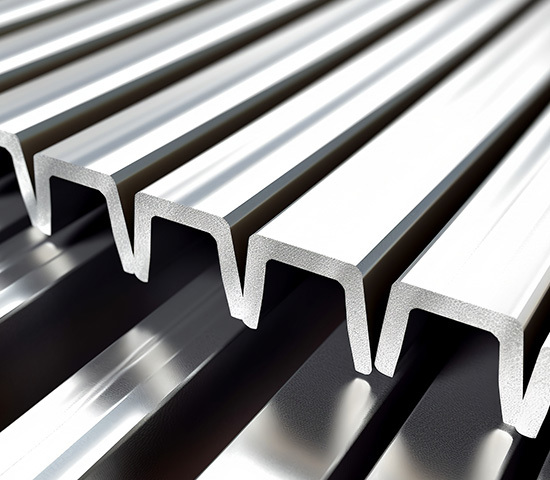

Aluminum ingot production line

HTGP Zinc and aluminum ingot automatic forming ingot casting machine (production line) is an important supporting equipment for smelting plants to reduce labor costs and expand production efficiency.

Deoxidized Aluminum Block Casting Production Line

The deoxidized aluminum block casting production line is highly automated. It has an excellent deoxidation effect and strong production flexibility.

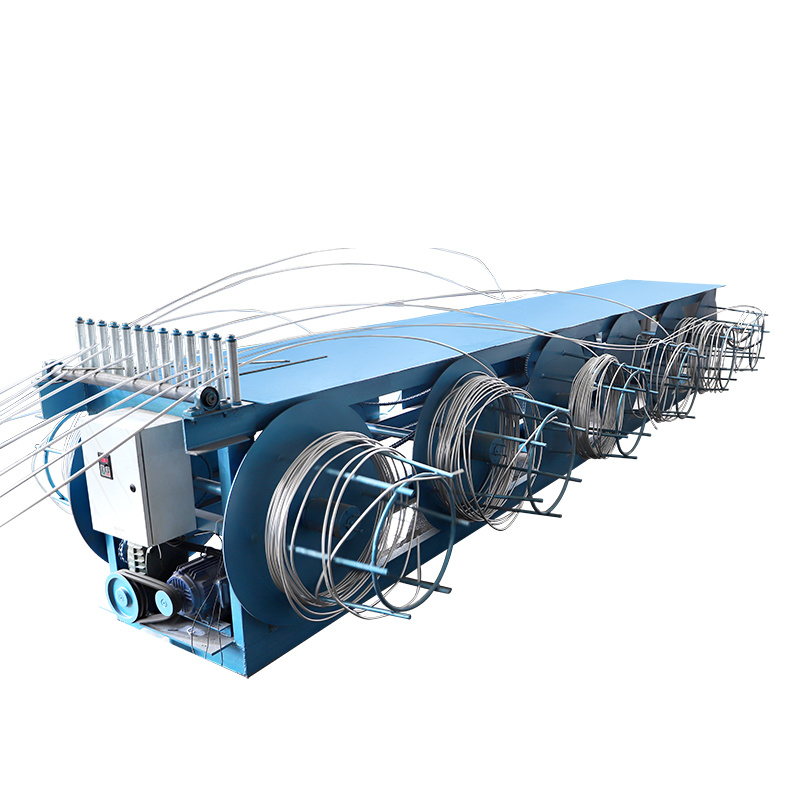

Aluminum rod horizontal continuous casting

HTGP aluminum rod horizontal continuous casting is mainly used to produce aluminum rods, copper rods and alloy rods with a diameter of 8-30mm, suitable for buyers with small and medium production capacity.

Hot Top Aluminium Billet Casting Machine

The hot top aluminum billet casting process is an efficient and precise casting method, which is suitable for producing aluminum rods with various alloy components.

We use optional cookies to improve your experience on our site, including through social media connections, and to serve personalized ads based on your online activity. If you refuse optional cookies, we will only use cookies that are necessary to provide you with the service. Privacy Statement

Leave your inquiry now, and get a systematic solution later.

We will contact you within one working day. Please pay attention to your email.