Gas-fired/Oil-fired aluminum melting furnace

Product Introduction

The natural gas furnaces produced by HTGP meet the national environmental protection standards, can be smoke-free, dust-free, and harmless, and reduce energy consumption and loss by 15%-25% compared with traditional related industrial equipment. The burner adopts imported burners, and each is equipped with a dedicated combustion controller to realize automatic ignition, flame detection, and flameout alarm of the burner. The equipment adopts tilting and tilting discharge, and then it is equipped with an automatic aluminum ingot casting production line to realize continuous production operations.

Product Features

1. Use natural gas or light crude oil as fuel, clean and safe.

2. It can be used for smelting non-ferrous metals such as aluminum, zinc, silver, lead, tin, copper, etc.

3. The capacity of the furnace ranges from 100kg to 5t and can be customized according to customer requirements.

4. The average energy consumption is 70m3/t or 85L/t, and it’s low energy consumption.

5. The design of multiple heat flow channels makes full use of the energy generated by the burner, greatly improving the thermal work efficiency, and the energy-saving effect is remarkable.

6. The power consumption is less than 10kW·h per pot, which is especially suitable for areas short of electricity.

7. The burners cannot be shared, that is, the burners using natural gas as fuel cannot be used for diesel oil, and vice versa.

8. The fuel is fully burned, and exhaust gas pollution is small and environmentally friendly.

0.1-1.5t Capacity | 1-4h/batch Melting Time | 70m3/85L Energy Consumption |

这里是答案

VIDEO PRESENTATION

PRODUCT DISPLAY

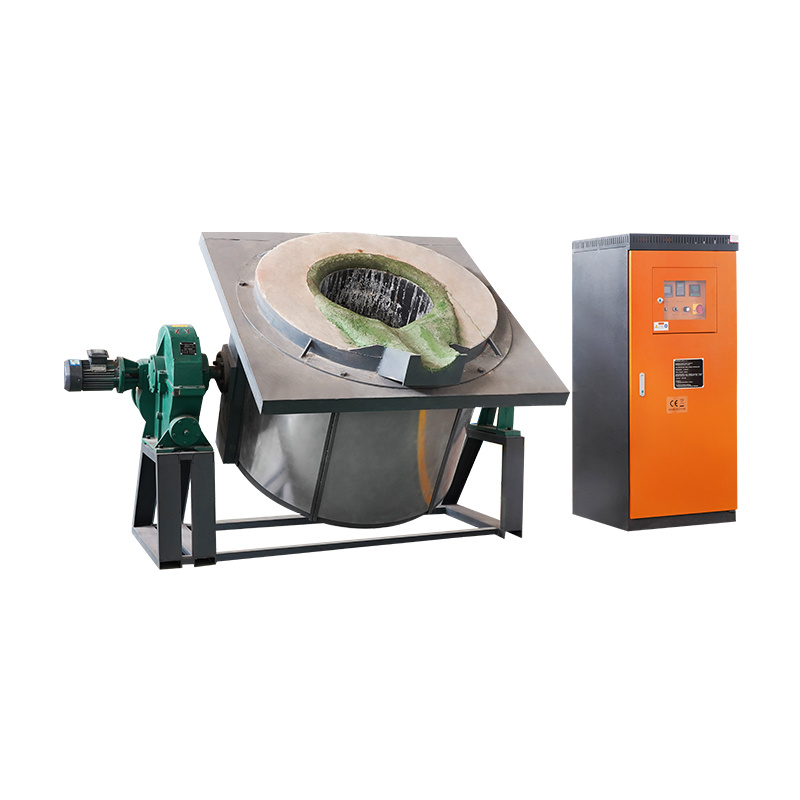

Gas-fired aluminum melting furnace

Gas-fired aluminum melting furnace2

Natural Gas Aluminum Melting Furnace 3

Natural Gas Aluminum Melting Furnace 2

RELATED MACHINES

Product Introduction Aluminum foil due to its strong, light weight, non-toxic, tasteless, moisture-proof, heat insulation, opaque, corrosion resistance, high conductivity, non-magnetic; Easy processing, coloring, printing, gloss and a series of advantages. Therefore, it has become the best material for food, beverage, tea, cigarettes, medicine, cosmetics and other packaging, and it is also an important material for manufacturing capacitors, cables, architectural decoration, textiles, vehicles, ships, aviation and other industries.The development of aluminum foil industry depends on the development of aluminum foil rolling mills. Since the industrialization of aluminum foil production in China, the most advanced technology and equipment of aluminum foil rolling in the world have been introduced, so that China's aluminum foil production has developed in the direction of large-scale, high-speed, automation and quality.Hongteng company closely follow the world's cutting-edge technology, constantly absorb and digest the latest technology, independent development, design, processing and manufacturing.The aluminum foil roughing mill is used for receiving sheet metal from cold rolling mill, 0.5 rolled to the thinnest 0.012 single zero aluminum foil, which is supplied to the foil finishing mill or the foil finishing mill for continuous rolling. Production Process The billet to be rolled is lifted to the inlet coil support, transported to the uncoiler by the coil trolley for tightening, rolled by the inlet deflector roll, the inlet tensioning roll, the work roll rolling, the outlet tensioning roll, and the flattening roll. After the winding is completed, the coil trolley is transported to the outlet coil support, and the sleeve lifting device removes the sleeve from the uncoiler. The sleeve is transferred to the coiling side at the bottom of the mill, and is sent to the coiler by the sleeve lifting device to complete one pass of rolling.

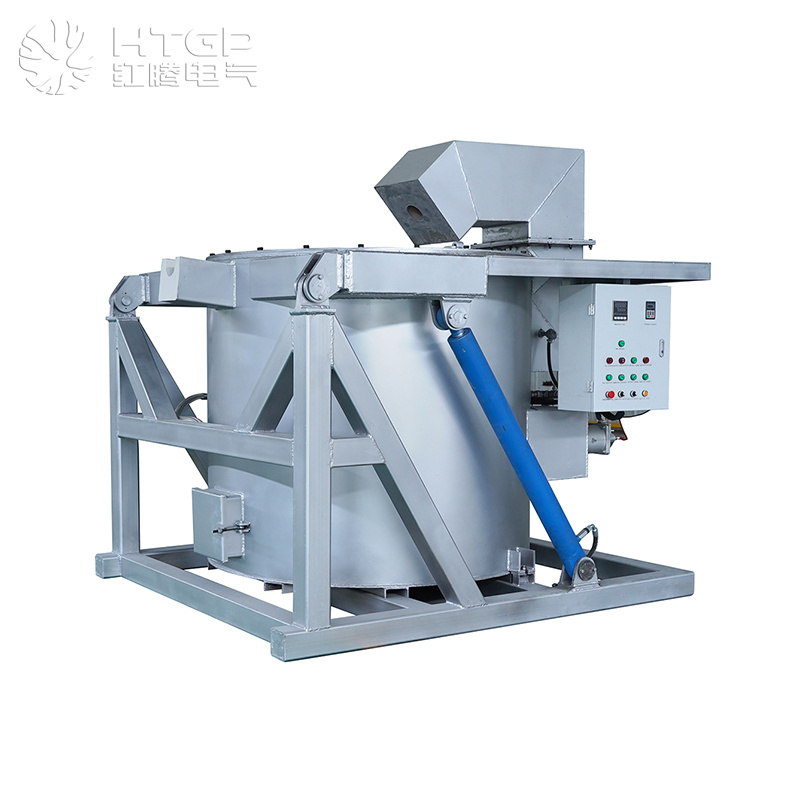

Reducer Tilting Aluminum Melting Furnace

The reducer tilting aluminum melting furnace is used to melt scrap aluminum, including cans, wires, etc. The capacity ranges from 100kg to 3 tons. Welcome to inquiry if you're interested.

Electric Aluminum Melting Furnace (Fixed)

HTGP electric induction aluminum melting furnace is suitable for smelting various scrap aluminum, such as waste cans and aluminum alloy materials. It has a fast melting speed, low burning loss rate, high recovery rate of 92%, and low power consumption.

Gas-fired/Oil-fired aluminum melting furnace

HTGP natural gas or light crude oil aluminum melting furnace can melt aluminum, copper, zinc, etc. It is specially designed for areas lacking electricity.

Fixed gas aluminum melting furnace

Product Introduction The fixed gas-fired aluminum melting furnace is a special aluminum smelting equipment, which can effectively heat and melt aluminum waste, and gradually melt the solid in the open flame heating.

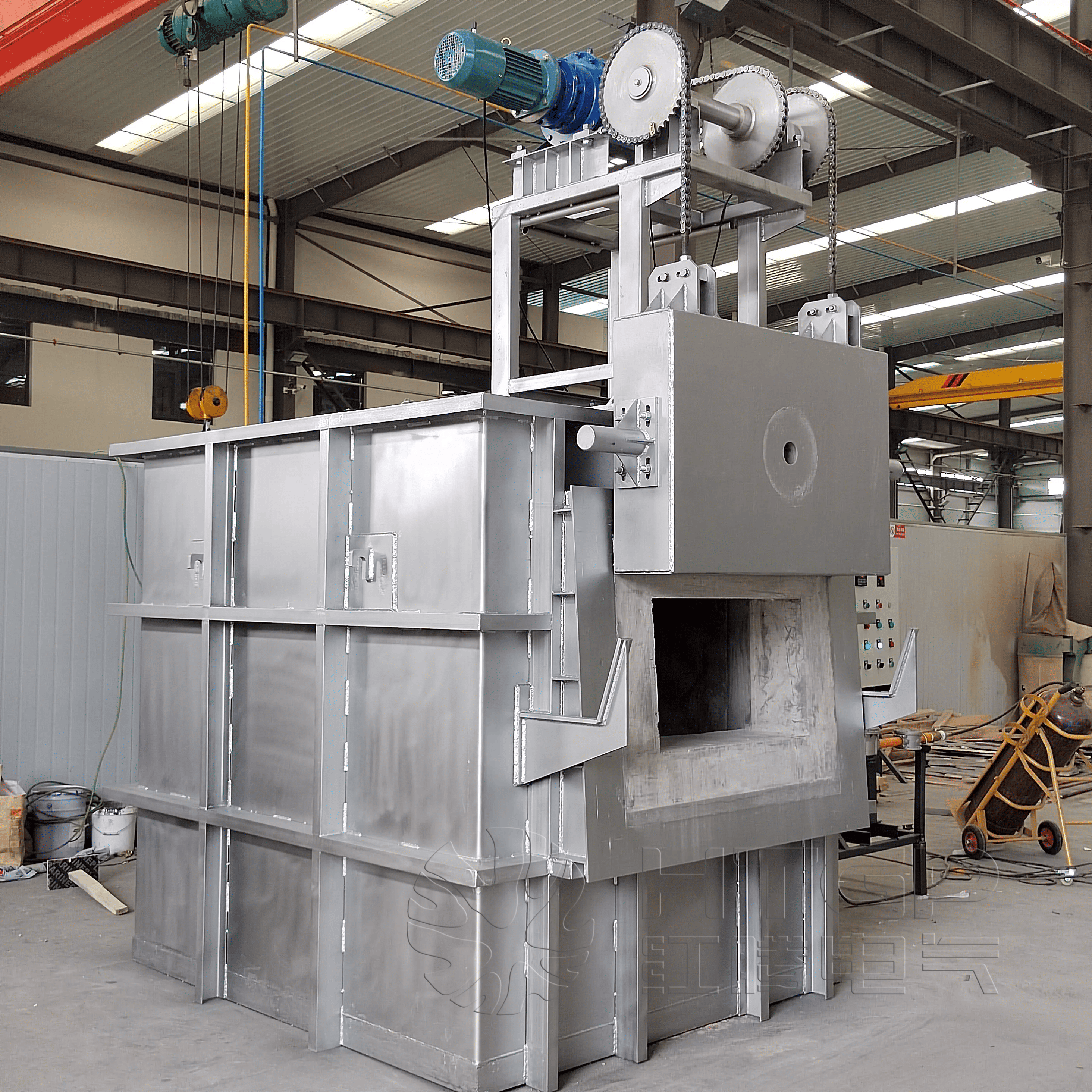

Regenerative Gas Aluminum Melting Furnace

Product IntroductionThis regenerative aluminum melting furnace is a melting furnace that places scrap aluminum or aluminum alloy and other rawmaterials into a melting pool, uses acombustion flame to melt them, remove impurities, and further adjust the alloy composition tomeet the required composition standards and temperature requirements ofthe process.

Aluminum ingot production line

HTGP Zinc and aluminum ingot automatic forming ingot casting machine (production line) is an important supporting equipment for smelting plants to reduce labor costs and expand production efficiency.

Hydraulic Tilting Aluminum Melting Furnace

The hydraulic tilting aluminum melting furnace has stable rotation and sufficient turning power and is widely used to produce aluminum ingots.

We use optional cookies to improve your experience on our site, including through social media connections, and to serve personalized ads based on your online activity. If you refuse optional cookies, we will only use cookies that are necessary to provide you with the service. Privacy Statement

Leave your inquiry now, and get a systematic solution later.

We will contact you within one working day. Please pay attention to your email.