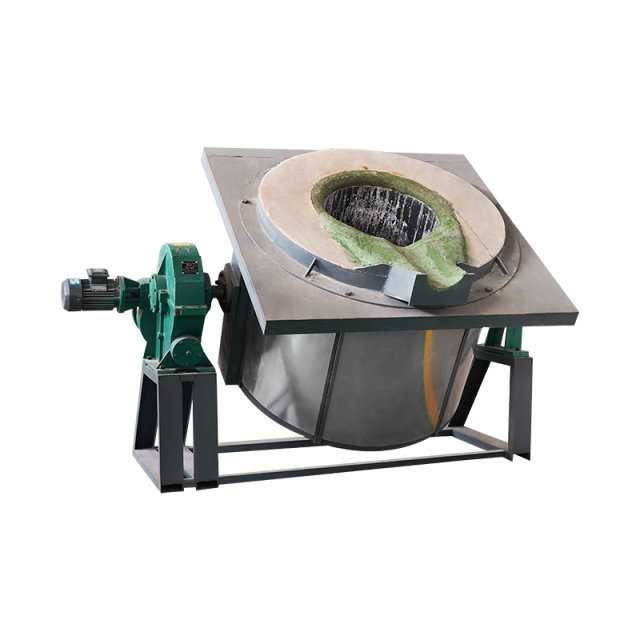

Metal Melting Furnace

Release time:

Mar 28,2025

source:

In metal heating furnaces, uncontrolled free air must be prevented from entering the furnace (see below for the reason). Therefore, the furnace must be kept slightly positive, both in furnaces with combustion products flowing in the furnace and in furnaces filled with protective gas.

The pressure at different heights in the furnace (measured from the furnace bottom) exceeds the atmospheric pressure by different values; the proof of this is found in the chapter "Gas Movement in the Furnace" in the previous volume.

Metal Melting Furnace

Therefore, the furnace pressure at the horizontal plane of the furnace bottom is usually taken as the standard. A pressure of 0.6 mm of water column is sufficient there. In a slab heating furnace with three zones (points) of heating at the end discharge, due to the effect of the hot gas column at the discharge end, a higher pressure should be maintained in order to achieve the purpose of heat preservation in the equalizing section.

It is difficult to read a pressure as small as 0.6 mm of water column on a water-filled U-tube pressure gauge, but such a small pressure is sufficient to produce a velocity of 3 to 6 m/s (depending on the temperature) in the furnace gas. If there is a small hole in the furnace door, the furnace gas will spray out from here, forming a "stream", the length of which indicates the size of the furnace pressure.

If the stream is transparent and almost invisible, it can be shown by letting dust fall on it or blowing smoke into it. If the stream length is not appropriate, the flue opening can be adjusted with a gate. Experienced heating workers pay attention to the relationship between the size of this stream and the amount of iron sheet generated on the heated workpiece.

These simple measurement methods were common to all industrial furnaces at the beginning of this century. And they are still applicable to furnaces without chimneys. The situation is similar for furnaces filled with protective gas. The positive pressure of these furnaces is generally less than 0.6 mm of water column. If the protective gas is non-flammable, it will extinguish the burning wax at the place where it flows out; if it is flammable, it can ignite the outflowing gas. If the finished product is not bright enough, it means that free air has entered.

Previous:

Next:

Previous

We use optional cookies to improve your experience on our site, including through social media connections, and to serve personalized ads based on your online activity. If you refuse optional cookies, we will only use cookies that are necessary to provide you with the service. Privacy Statement

Leave your inquiry now, and get a systematic solution later.

We will contact you within one working day. Please pay attention to your email.