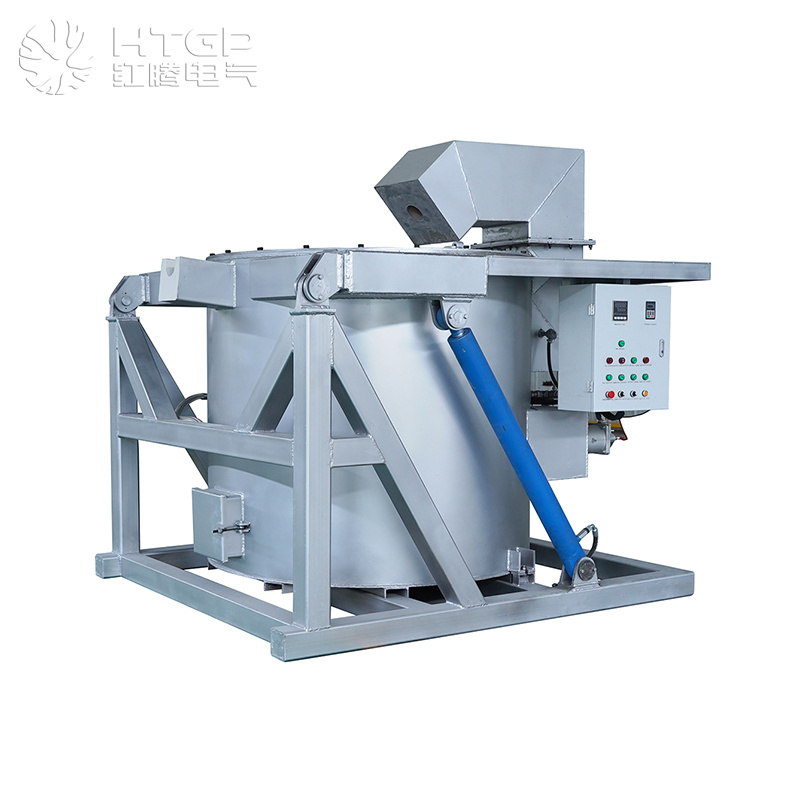

Aluminum Thermite Melting Furnace

Release time:

Jul 08,2025

source:

Aluminum Thermite Melting Furnace: Innovative Solution for High-Temperature Metal Reactions

In high-temperature metallurgy, the Aluminum Thermite Melting Furnace plays a crucial role in enabling fast, localized melting reactions through thermite-based processes. Designed for precision, efficiency, and safety, this specialized furnace is engineered to handle the extreme exothermic reactions generated by aluminum-based thermite compositions. It is particularly valuable in applications where traditional melting technologies are too slow, energy-intensive, or unsuitable due to location or material constraints.

This product plan outlines the features, advantages, and market potential of our advanced aluminum thermite melting furnace, aimed at meeting the needs of international users in metallurgy, rail welding, military engineering, and specialty alloy production.

What is an Aluminum Thermite Melting Furnace?

An Aluminum Thermite Melting Furnace is a purpose-built device used to initiate and control thermite reactions, in which aluminum powder reacts with metal oxides (such as iron oxide or copper oxide) to produce molten metal at temperatures exceeding 2500°C. This highly exothermic reaction can melt steel or other high-melting-point metals within seconds.

Unlike traditional electric arc or induction melting furnaces, this system uses chemical energy, allowing it to:

Operate without external electricity (in field applications)

Achieve extremely high localized temperatures

Rapidly melt small to medium quantities of metal

Core Components of the Furnace

Our Aluminum Thermite Melting Furnace System includes a robust and modular design suited for controlled industrial and field operations.

Reaction Crucible

Made from high-alumina or fused silica ceramic

Resists extreme thermal shock and metal corrosion

Optional single-use or reusable crucibles

Ignition System

Electronic or magnesium-based ignition devices

Delayed start mechanism for operator safety

Remote control ignition available

Pouring Mechanism

Precision gating system for controlled metal flow

Slag separation chamber to ensure purity

Pre-mold positioning unit for field casting

Safety and Containment

Heat-resistant insulation and refractory lining

Overpressure release vents

Dust and fume extraction compatible design

Key Applications

The aluminum thermite melting process is widely used in:

Railway Track Welding

Known as thermite welding, this method joins rail sections by generating molten steel through thermite reactions.

Specialty Alloy Production

Production of ultra-pure metals and alloys (e.g., chromium, vanadium) through thermite reduction.

Military and Defense

Emergency repair kits and demolition tools using thermite for field operations.

Scientific Research and Education

Demonstrations and controlled experiments on combustion and metallurgy.

Technical Specifications

Reaction Temperature: > 2500°C (4532°F)

Melting Capacity: 0.5 kg – 20 kg per cycle

Cycle Time: 30 seconds – 5 minutes

Crucible Material: Al₂O₃, SiO₂, or MgO

Optional Integration: Portable frame, mold alignment tool, fume hood

Competitive Advantages

Extreme Temperature Capability

The aluminum thermite furnace can achieve higher melting temperatures than most conventional furnaces, making it suitable for reactive metals and quick-fusion tasks.

Portability and Versatility

Its compact, modular design allows use in remote locations, outdoor worksites, or mobile foundries — a major benefit for rail and field operations.

Cost Efficiency

Since no external energy source is needed once ignited, it reduces operating costs and energy consumption, particularly in batch processes.

Environmental Adaptability

The process emits no toxic gases and generates minimal waste. Optional filters can be added for emission-sensitive environments.

Target Market and Global Demand

Our Aluminum Thermite Melting Furnace is tailored for the following sectors:

Railway maintenance companies

Metal research laboratories

Military contractors and field engineers

Foundries and specialty alloy manufacturers

Technical universities and training centers

Target Export Regions:

North America (USA, Canada)

Europe (Germany, Poland, UK)

South Asia (India, Pakistan)

Middle East (Saudi Arabia, UAE)

Africa (Nigeria, South Africa)

These regions show growing investment in infrastructure, research, and military engineering — all key industries using thermite-based solutions.

Previous:

Next:

Previous

We use optional cookies to improve your experience on our site, including through social media connections, and to serve personalized ads based on your online activity. If you refuse optional cookies, we will only use cookies that are necessary to provide you with the service. Privacy Statement

Leave your inquiry now, and get a systematic solution later.

We will contact you within one working day. Please pay attention to your email.