HTGP Aluminum Furnaces: The Most Powerful Helper for Continuous Casting

HTGP is a unique Chinese manufacturer headquartered in Luoyang, China, specializing in the design and manufacture of Reducer Tilting Aluminum Melting Furnaces, Hydraulic Tilting Aluminum Melting Furnaces, Gas-fired/Oil-fired Aluminum Melting Furnaces, Aluminum Ingot Production Lines, Aluminum Rod Continuous Casting and Rolling, Aluminum plate Rolling mill, providing high-quality equipment for the smelting of non-ferrous metals such as the aluminum, copper, zinc, etc.

High Quality Comes from Profession

■ 6 production workshops

■ 12 years of industry experience

■ 20+ research & develop personnel

■ 100+ industry patents

■ 7000+ square meters of workshop area

Product Introduction The closed cooling tower is mainly used to provide cooling effect on high power heating element sand furnace induction coil, so as to ensure the normal operation of the equipment.The circulating system uses 304 stainless steel/copper tube cooling pipe, with small resistance, fast heat dissipation,and lowering water temperature. Pure copper core waterproof motors, strong power, energy saving and power saving. long service life. Product Features 1.Use demineralize water as the coolant, do not contact with air, do not deteriorate and scale, to ensure the best cooling effect.2.Low loss of circulating water.3.There are water collector on the spray system for water collection and fog collection with less water consumption.4.Convenient disassemble and assembly, low operation costs and low maintenance costs.5.Compact structure, small land occupied and convenient installation.6.Less quick-wear parts, low failure rate, convenient maintenance.7.Intelligent control, energy saving and environmental protection.

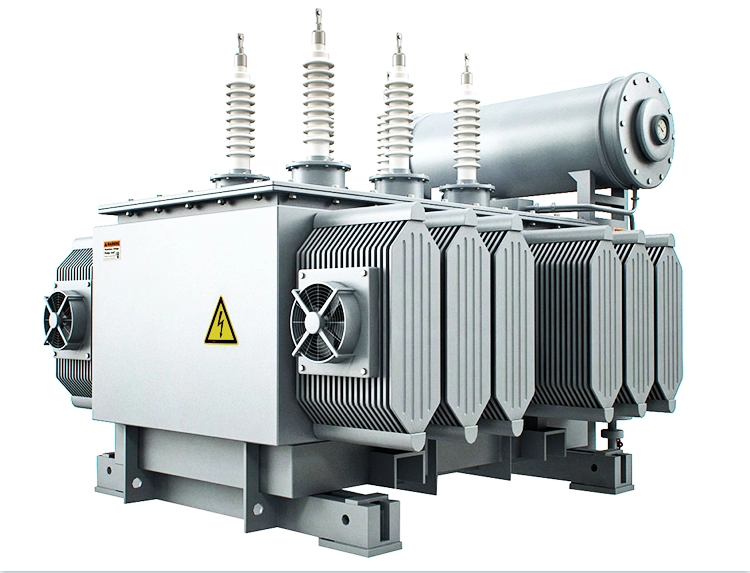

Product Introduction Transformers are the basic equipment for power transmission and distribution. In an AC circuit, a transformer can increase or decrease the voltage, and convert any value of voltage into a voltage value with the same frequency, so as to meet the requirements of transmission, distribution and use of electric energy. Transformers can be divided into power transformers, instrument transformers, test transformers and special transformers according to different uses.Product Features 1. The iron core is made of high magnetic permeability cold-rolled silicon steel sheet, the surface of the iron core is covered with protective resin and vacuum drying technology, and the process flow conforms to international standards;2. The finished transformer has the advantages of flame retardant, self-extinguishing, moisture-proof, rust-proof, and good heat dissipation, and can penetrate into the load center.3. The finished transformer is suitable for various places such as various workshops, steel mills, power plants or complete substations.4. The finished transformer adopts a non-suspending structure, which can withstand strong bumps during transportation.5. Compact structure, small footprint, easy installation.6. Few wearing parts, low failure rate, easy maintenance.

Deoxidized Aluminum Block Casting Production Line

The deoxidized aluminum block casting production line is highly automated. It has an excellent deoxidation effect and strong production flexibility.

Aluminum rod horizontal continuous casting

HTGP aluminum rod horizontal continuous casting is mainly used to produce aluminum rods, copper rods and alloy rods with a diameter of 8-30mm, suitable for buyers with small and medium production capacity.

Hot Top Aluminium Billet Casting Machine

The hot top aluminum billet casting process is an efficient and precise casting method, which is suitable for producing aluminum rods with various alloy components.

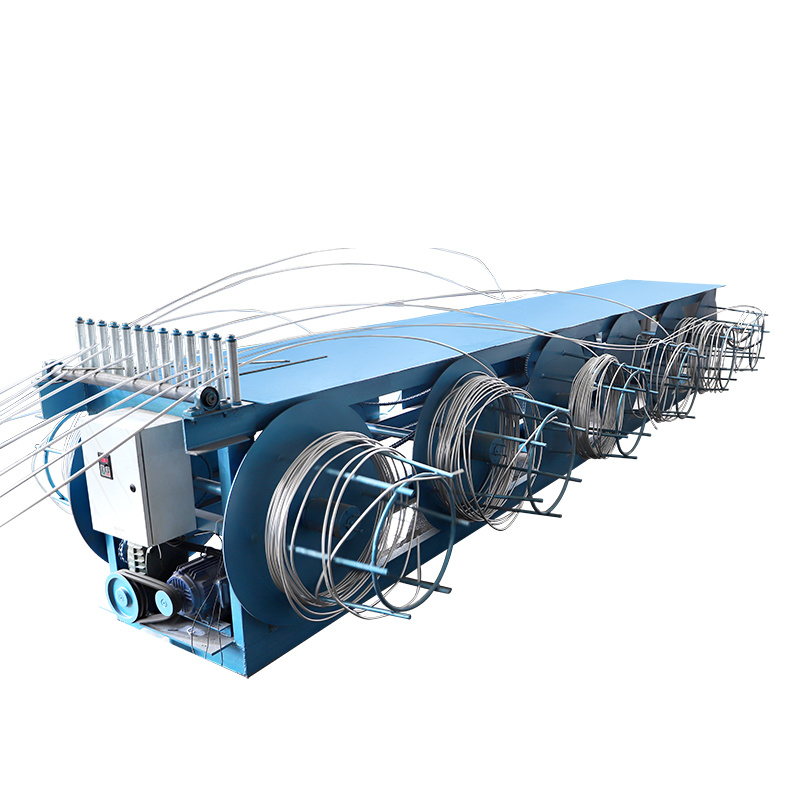

Aluminum rod continuous casting and rolling

The ingot is evenly stressed during the rolling process so that the aluminum rod and aluminum alloy rod are fully deformed, and the mechanical properties of the products are excellent.

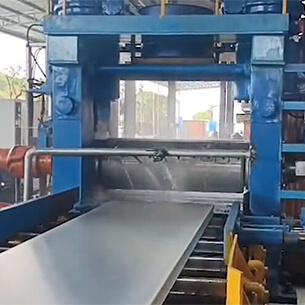

The aluminum plate rolling mill is independently driven by a tension roller DC motor. It has the characteristics of a wide straightening range, high tension, and speed precision.

The aluminum cast rolling mill production line is of low investment, small floor space, short construction period, and quick profit.

We use optional cookies to improve your experience on our site, including through social media connections, and to serve personalized ads based on your online activity. If you refuse optional cookies, we will only use cookies that are necessary to provide you with the service. Privacy Statement

Leave your inquiry now, and get a systematic solution later.

We will contact you within one working day. Please pay attention to your email.