Induction melting equipment

Release time:

Oct 23,2025

source:

Choosing the Right Induction Melting Equipment in 5 Steps

Step 1: Define Your Melting Requirements and Metal Type

Before you even look at models or prices, ask yourself: What exactly am I trying to melt—and how much of it?

This isn’t just about volume. Different metals react differently to electromagnetic fields. Some heat fast. Others need more time. Get this step wrong, and your furnace might underperform—or worse, damage your material.

Understanding Common Metals Processed in Induction Furnaces

Induction furnaces handle a wide range of metals. According to Induction Technology Corporation, common ones include iron, steel, brass, aluminum, and precious metals like gold and silver.

Each has unique electrical conductivity and melting points. For example: - Steel melts around 1,370–1,510°C - Aluminum melts at roughly 660°C - Copper alloys sit between 900–1,100°C

The key point? Your furnace must be compatible with the thermal and conductive properties of your target metal.

Have you ever tried melting aluminum in a setup designed for iron? It doesn’t go well. Too much power too fast leads to overheating, oxidation, and inconsistent pour quality.

So start by listing every metal you plan to process. Then verify whether the furnace is rated for those materials.

Matching Furnace Frequency to Material Conductivity

Here’s something many overlook: frequency matters.

Low-frequency systems (50–60 Hz) work best for large volumes of highly conductive metals like copper or aluminum. They penetrate deeper into the charge, creating uniform heating.

High-frequency units (1 kHz and above) are better suited for smaller batches or less conductive materials. Think precious metals or specialty alloys.

A mismatch here causes inefficient coupling—meaning poor energy transfer and longer melt cycles.

Want to avoid guesswork? Reach out to manufacturers early. As noted on amelt.com, experienced suppliers can advise which frequencies suit specific metals.

Assessing Batch Size vs. Continuous Melting Needs

Are you running short runs with frequent changeovers? Or is this a high-volume, continuous operation?

If you're doing batch melting, a coreless furnace gives flexibility. You can switch between different alloys quickly.

But if you need constant molten metal supply—for casting lines or holding during off-peak hours—a channel-type furnace may be smarter. These excel at maintaining temperature over long periods.

Ask yourself:

Do I need speed and versatility? → Lean toward batch-capable systems.

Or do I prioritize steady output and energy savings during idle times? → Consider holding-capable designs.

Your production rhythm should drive the choice—not the other way around.

Step 2: Evaluate Power Capacity and Energy Efficiency

Power isn’t just about “bigger is better.” It’s about matching kW to your actual needs.

Too little power, and your melt cycle drags on. Too much, and you’re burning electricity unnecessarily.

Let’s break it down.

Calculating Required kW Based on Melting Rate and Alloy

How much metal do you need melted per hour? That number drives your power requirement.

For instance, melting 1 ton of steel per hour typically requires around 450–500 kW, depending on efficiency and starting temperature. This aligns with data from firstfurnace.com, which lists a 1-ton / 450kW intermediate frequency induction furnace as a standard configuration.

But don’t stop there.

Different alloys absorb heat differently. Stainless steel takes more energy than gray iron. Aluminum needs careful control despite lower melting temps.

Use this rule of thumb:

Total kW ≈ (Melt rate in kg/hour × Specific energy in kWh/kg)

Specific energy varies: - Cast iron: ~550–600 kWh/ton - Steel: ~600–650 kWh/ton - Aluminum: ~650–750 kWh/ton (due to oxide layer)

Still unsure? Plug in your numbers and talk to an engineer. Most reputable companies offer free consultations.

Comparing Thermal Efficiency Across Modern Induction Systems

Not all furnaces convert electricity to heat equally.

Modern mid-frequency induction systems boast thermal efficiencies of 65–75%, meaning two-thirds of input power actually goes into melting.

Older or poorly maintained units might drop below 50%. That’s half your electricity bill going up in heat loss.

Look for features like water-cooled coils, optimized busbar design, and advanced insulation. These reduce parasitic losses.

Also consider the inverter technology. IGBT-based inverters tend to be more efficient than thyristor types, especially at partial loads.

Is your shop running multiple shifts? Even a 10% efficiency gain could save thousands per year.

Integrating Power Factor and Duty Cycle into Selection

Here’s a sneaky cost driver: poor power factor.

Induction furnaces draw reactive power, which utilities often penalize unless corrected. A low power factor means higher apparent current, stressing transformers and cables.

Modern systems come with built-in power factor correction (PFC), keeping values above 0.9. Ask for this spec upfront.

Then there’s duty cycle—the percentage of time the furnace operates at full load.

Foundries running 24/7 need robust cooling and durable components. Intermittent users can opt for lighter builds.

Bottom line: Don’t just check peak kW. Examine how the system performs under your real operating conditions.

Step 3: Choose the Appropriate Induction Furnace Type

Now we get into the hardware. Three main types dominate industrial use:

| Furnace Type | Best For | Key Advantage | Limitation |

|---|---|---|---|

| Coreless | Foundries, alloy changes | Flexibility, fast startup | Refractory wear, batch-only |

| Channel | Holding, superheating | Continuous flow, energy-efficient | Limited alloy switching |

| Vacuum/Crucible | Specialty metals | Contamination-free melts | High cost, complex |

Let’s dig into each.

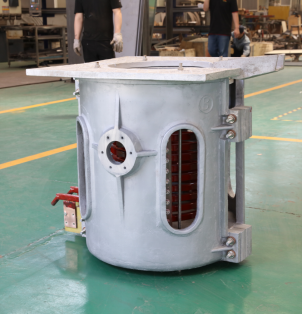

Coreless Induction Furnaces: Versatility for Foundries

These are the workhorses of most jobbing foundries.

They use a water-cooled coil surrounding a refractory-lined crucible. No iron core—just electromagnetic induction directly heating the charge.

Why choose one? - Fast melting - Easy alloy changes - Clean process (no fuel combustion) - Scalable from small labs to multi-ton setups

As highlighted by acrossinternational.com, these are ideal when flexibility is king.

But they demand regular maintenance. The refractory lining erodes over time. And because they operate in batches, you’ll have downtime between pours.

Channel-Type Furnaces: Ideal for Holding and Superheating

Think of these as "molten metal keepers."

They feature a looped channel filled with metal, acting as a secondary winding. Once charged, they maintain temperature efficiently.

Best used for: - Holding molten iron or copper between melts - Superheating before casting - Continuous feeding of die-casting machines

Their biggest advantage? Lower standby losses. Since the loop stays hot, reheating uses less energy.

But they’re picky about alloys. Switching from iron to aluminum isn’t practical without a full rebuild.

So if your operation runs one metal 24/7, a channel furnace could cut costs significantly.

Vacuum and Crucible Variants for Specialty Alloys

Working with titanium, zirconium, or aerospace-grade nickel alloys?

Then contamination is your enemy.

Vacuum induction melting (VIM) furnaces solve this. They melt metal in a sealed chamber under vacuum or inert gas.

Benefits: - Ultra-pure melts - Precise chemistry control - Ability to add reactive elements safely

Used widely in defense, medical implant, and jet engine manufacturing.

Downside? Cost and complexity. These aren’t plug-and-play systems. Training, safety protocols, and maintenance are intensive.

But for mission-critical applications where purity equals performance, there’s no substitute.

Check offerings from specialists like those mentioned on electroheatinduction.com, who serve aerospace and military sectors.

Step 4: Consider Refractory Lining and Maintenance Demands

You could have the most powerful furnace on the market—but if the lining fails, you’re dead in the water.

Refractory life impacts uptime, labor costs, and overall profitability.

Selecting Refractory Materials by Melt Chemistry

Not all linings are created equal.

Acidic linings (like quartz) work well for cast iron and carbon steels. But they degrade fast with basic slags or high-oxidation processes.

Basic linings (magnesia-based) handle stainless steel and high-alloy steels better. However, they’re fragile and sensitive to moisture.

And neutral linings (alumina-based)? Great compromise for mixed operations.

Match the lining to your typical melt chemistry. One misstep and you’ll face premature erosion or—even worse—a breakout.

Pro tip: Keep spare liners on hand if you run aggressive chemistries. Downtime waiting for delivery kills productivity.

Estimating Liner Life and Downtime Costs

How long does a lining last?

It depends. A well-maintained coreless furnace melting gray iron might get 150–200 heats. The same unit processing stainless could see only 80–100.

Monitor condition regularly. Look for cracks, thinning, or spalling.

When relining, expect 1–3 days of downtime. Labor, materials, and lost production add up.

One study cited on ceramicsrefractories.saint-gobain.com notes proper installation and curing are critical to maximizing lifespan.

Rushing the dry-out cycle? That’s a fast track to cracking.

Automation Features That Reduce Operational Burden

Can you automate any part of the process?

Modern systems offer: - Auto-tapping controls - Remote monitoring via app - Predictive maintenance alerts - Integrated weighing and dosing

These don’t just save labor—they reduce human error.

Imagine setting a melt schedule overnight and waking up to ready-to-pour metal. Or getting a notification when coil water pressure drops.

Small investments in automation often pay back fast in reduced scrap and consistent quality.

Talk to vendors about digital integration. Is SCADA compatibility available? Can it log melt history for traceability?

In today’s connected factories, your furnace shouldn’t be a孤岛.

Step 5: Assess Total Cost of Ownership and Supplier Support

Let’s be honest: the sticker price is just the beginning.

A cheaper furnace can end up costing more over five years due to inefficiency, repairs, and downtime.

Upfront Investment vs. Long-Term Operating Expenses

Yes, some brands cost more upfront. But what about: - Energy consumption? - Refractory replacement frequency? - Spare parts pricing? - Service availability?

Compare total cost of ownership (TCO), not just initial quotes.

For example, a furnace with superior insulation might cost 15% more—but save 20% on power annually. Payback period? Often under three years.

Always request a TCO estimate from the supplier. If they can’t provide one, that’s a red flag.

Evaluating Warranty, Service Network, and Training Access

Who fixes it when it breaks?

Even the best equipment fails occasionally. What matters is how fast you’re back online.

Ask: - Is there local technical support? - Do they stock critical spares nearby? - Is operator training included?

Induction Technology Corporation, for instance, emphasizes decades of experience and global support, as noted on their site inductiontech.com.

That kind of backing matters when your line is down and customers are waiting.

Also, check warranty terms. Does it cover labor? What voids coverage? Read the fine print.

Confirming Compliance with Safety and Environmental Standards

Finally, ensure compliance.

Are emissions within limits? Is noise controlled? Are emergency shutdowns properly implemented?

In many regions, induction furnaces fall under OSHA, CE, or ISO standards. Non-compliant installations risk fines—or worse, accidents.

Verify that the equipment meets local codes before purchase.

And don’t forget documentation. Proper manuals, schematics, and safety labels should come standard.

Common Questions

Q1: What factors determine the optimal frequency for an induction melting furnace?

The optimal frequency depends on the size of the charge and the metal's resistivity. Larger charges and highly conductive metals like aluminum benefit from lower frequencies (50–60 Hz), which allow deeper current penetration. Smaller or less conductive materials, such as precious metals, perform better at higher frequencies (1–10 kHz). Matching frequency ensures efficient coupling and avoids uneven heating or excessive stirring. For guidance tailored to your application, consult experts like those at Inductotherm Corp.

Q2: How do I calculate the right furnace capacity for my production volume?

Start by determining your hourly or shift-based melt requirement. For example, if you need to produce 5 tons of molten metal per 8-hour shift, that’s roughly 625 kg/hour. Use this number to select a furnace with sufficient melt rate. Remember to account for auxiliary tasks like pouring, skimming, and relining. A good rule is to add 20–30% buffer to your nominal capacity. Manufacturers like Induction Technology Corporation can help model your workflow and recommend suitable sizes.

Q3: What are the key differences between coreless and channel induction furnaces for industrial use?

Coreless furnaces are ideal for batch melting and frequent alloy changes. They offer fast startup and flexibility but require periodic relining. Channel furnaces, on the other hand, are designed for continuous holding and superheating. They’re more energy-efficient during idle periods but less flexible when switching metals. Choose coreless for job shops and R&D; go channel-type for high-volume, single-alloy operations. More details on operational trade-offs can be found at Electroheat Induction.

Previous:

Next:

Previous

Next

We use optional cookies to improve your experience on our site, including through social media connections, and to serve personalized ads based on your online activity. If you refuse optional cookies, we will only use cookies that are necessary to provide you with the service. Privacy Statement

Leave your inquiry now, and get a systematic solution later.

We will contact you within one working day. Please pay attention to your email.